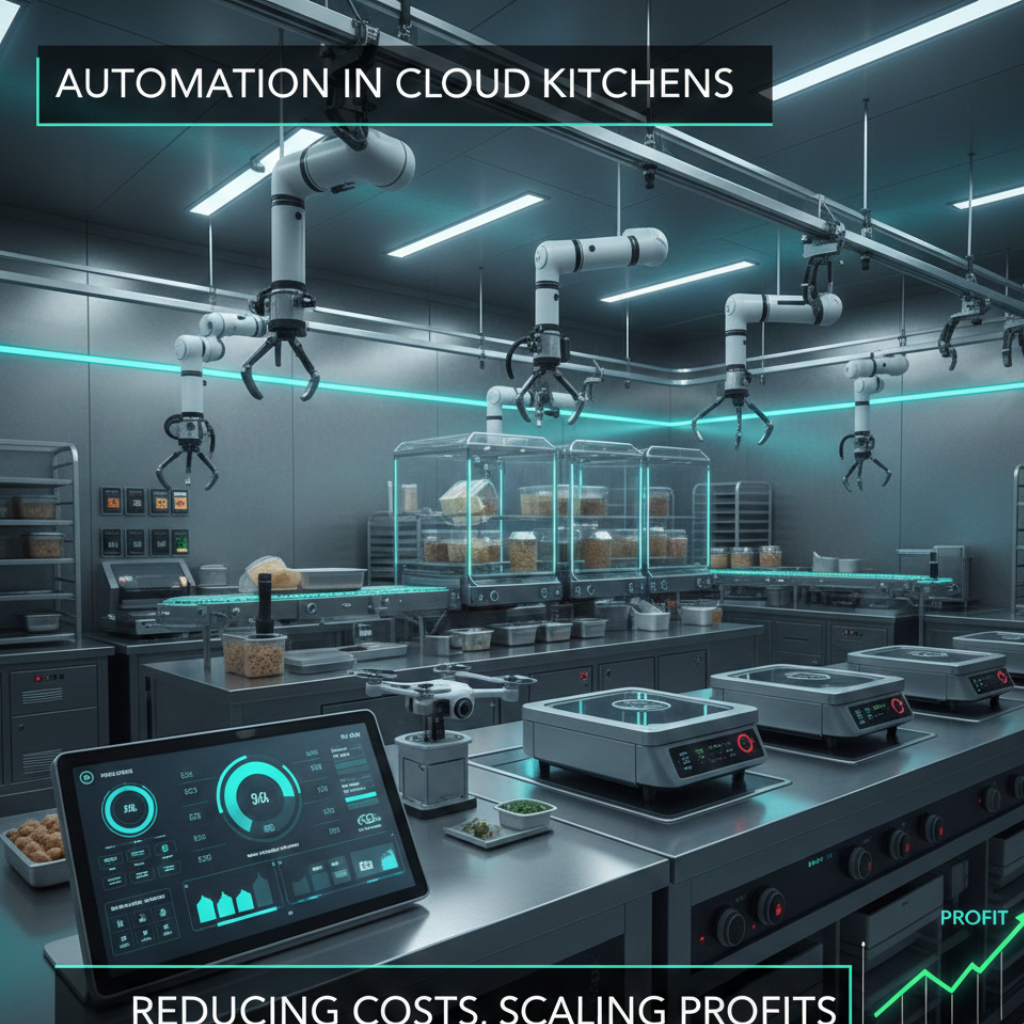

Automation in Cloud Kitchens is no longer a futuristic concept in the food industry. In India’s fast-growing cloud kitchen ecosystem, smart automation is becoming a necessity rather than a luxury. With rising competition, thin margins, and increasing operational complexity, cloud kitchens are turning to automation to survive, scale, and stay profitable. Cloud Kitchen Business in India

From automated order management and inventory tracking to smart kitchen workflows and delivery optimization, automation is reshaping how cloud kitchens operate. In this in-depth guide, we explore how automation in cloud kitchens is reducing costs, improving efficiency, and enabling food brands to scale profits sustainably.

1. Why Cloud Kitchens Need Automation

Cloud kitchens operate in a high-pressure environment where speed, accuracy, and consistency determine success. Manual operations often struggle to keep up with growing order volumes and complex workflows.

Common challenges faced by non-automated cloud kitchens include:

- High manpower dependency

- Order processing errors

- Inventory mismanagement

- Food wastage

- Inconsistent preparation times

Automation addresses these pain points by standardizing and optimizing daily operations.

2. What Automation Means in Cloud Kitchen Operations

Automation in cloud kitchens refers to the use of technology-driven systems that reduce manual intervention in repetitive and decision-heavy processes.

Key areas where automation is applied include:

- Order management

- Inventory tracking

- Kitchen workflows

- Staff scheduling

- Delivery coordination

By automating these functions, cloud kitchens gain better control, visibility, and scalability.

3. Automated Order Management Systems

One of the most impactful areas of automation is order management.

3.1 Centralized Order Dashboard

Automated systems consolidate orders from multiple delivery platforms into a single dashboard, eliminating manual switching between apps.

3.2 Error Reduction

Automation minimizes:

- Missed orders

- Wrong item preparation

- Delayed confirmations

This directly improves customer satisfaction and ratings.

4. Inventory Automation & Cost Control

Inventory is one of the largest cost drivers in cloud kitchens. Automation helps optimize inventory usage and reduce wastage.

4.1 Real-Time Stock Updates

Automated inventory systems update stock levels instantly as orders are processed.

4.2 Smart Reordering

Based on consumption patterns, systems automatically alert or place reorders, preventing stock-outs and overstocking.

According to insights shared by Statista, cost optimization is becoming critical for food delivery businesses in India.

5. Kitchen Workflow Automation

Automation inside the kitchen improves speed, consistency, and output quality.

- Automated order sequencing

- Standardized preparation steps

- Real-time preparation timers

Smart kitchen displays guide staff on what to cook next, reducing confusion during peak hours.

6. Manpower Optimization Through Automation

Labor costs are a major expense for cloud kitchens. Automation helps use manpower more efficiently.

6.1 Smart Staff Scheduling

Automated scheduling tools align staff availability with predicted demand.

6.2 Reduced Training Time

Standardized workflows reduce dependency on highly skilled chefs, making training faster and cheaper.

7. Automated Menu Engineering

Automation supports smarter menu decisions by analyzing performance data.

- Identifying high-margin dishes

- Removing slow-moving items

- Optimizing portion sizes

This ensures the menu remains profitable and operationally efficient.

8. Delivery & Dispatch Automation

Delivery speed and accuracy are critical for cloud kitchens.

8.1 Automated Dispatch Timing

Systems estimate preparation time and trigger delivery partner assignment automatically.

8.2 Fewer Cancellations

Accurate ETAs reduce customer cancellations and improve platform rankings.

Delivery workflow insights are widely discussed by Restaurant India.

9. Automation-Driven Analytics & Reporting

Automation generates real-time reports that help founders make data-driven decisions.

Key metrics tracked include:

- Daily sales performance

- Food cost percentage

- Wastage levels

- Staff productivity

Better visibility leads to faster corrective actions.

10. How Automation Reduces Costs & Increases Profits

Cloud kitchens that implement smart automation typically see:

- 10–20% reduction in food wastage

- Lower manpower costs

- Faster order turnaround

- Higher customer ratings

These improvements directly translate into higher net profit margins.

11. Automation as a Scaling Enabler

Automation makes scaling cloud kitchens easier and less risky.

Standardized systems allow:

- Faster onboarding of new locations

- Consistent quality across kitchens

- Centralized control over operations

Without automation, scaling often leads to chaos and losses.

12. Challenges in Implementing Automation

Despite its benefits, automation adoption comes with challenges:

- Initial setup costs

- System integration issues

- Staff resistance to change

- Data accuracy dependency

However, these challenges are short-term compared to long-term gains.

13. Future of Automation in Cloud Kitchens

The future of cloud kitchens in India will be heavily automation-driven.

Upcoming advancements include:

- Robotic cooking assistants

- Voice-controlled kitchen systems

- Predictive maintenance for equipment

- Fully integrated AI-automation platforms

Automation will become a competitive necessity rather than an option.

14. Final Thoughts: Automation as a Profit Multiplier

Automation in cloud kitchens is no longer about convenience-it is about survival and scalability. In a business where margins are thin and execution matters daily, smart automation provides the control, efficiency, and consistency needed to reduce costs and scale profits.

Cloud kitchens that invest in automation today will be the ones leading India’s food delivery market tomorrow.

Frequently Asked Questions (FAQs)

Q1. What is automation in cloud kitchens?

Automation refers to using technology to manage orders, inventory, workflows, and analytics with minimal manual intervention.

Q2. Does automation reduce cloud kitchen costs?

Yes, automation reduces food wastage, manpower dependency, and operational errors, lowering overall costs.

Q3. Is automation suitable for small cloud kitchens?

Yes, many automation tools are scalable and affordable for small and medium cloud kitchens.

Q4. Can automation help in scaling cloud kitchens?

Absolutely. Automation standardizes operations, making multi-location expansion easier and more profitable.

People Also Read

- AI in Cloud Kitchen Operations

- Cloud Kitchen Trends 2025

- Cloud Kitchen Survival Strategies

- Cloud Kitchen Profitability Case Study