Cloud Kitchen Profitability Consultant in India

Orders don’t guarantee profit. We help cloud kitchens see, protect, and scale margins by fixing food cost leaks, portion drift, discount chaos, and refund losses using data-backed operational systems.

Why Cloud Kitchens Struggle to Stay Profitable

Most cloud kitchens don’t lose money suddenly. They lose it slowly through small daily leaks that compound as orders grow.

Food Cost Drift

Over-portioning, yield loss, and over-prep quietly erode margin.

Discount Dependency

Orders rise, but contribution margin shrinks.

Refunds & Ratings

Packing errors and delays create hidden CAC.

No Profit Visibility

Founders don’t know which items actually make money.

What a Cloud Kitchen Profitability Consultant Actually Does

Profitability consulting is not advice. It is building systems that make every order financially predictable.

Unit Economics

Contribution margin per order and per SKU.

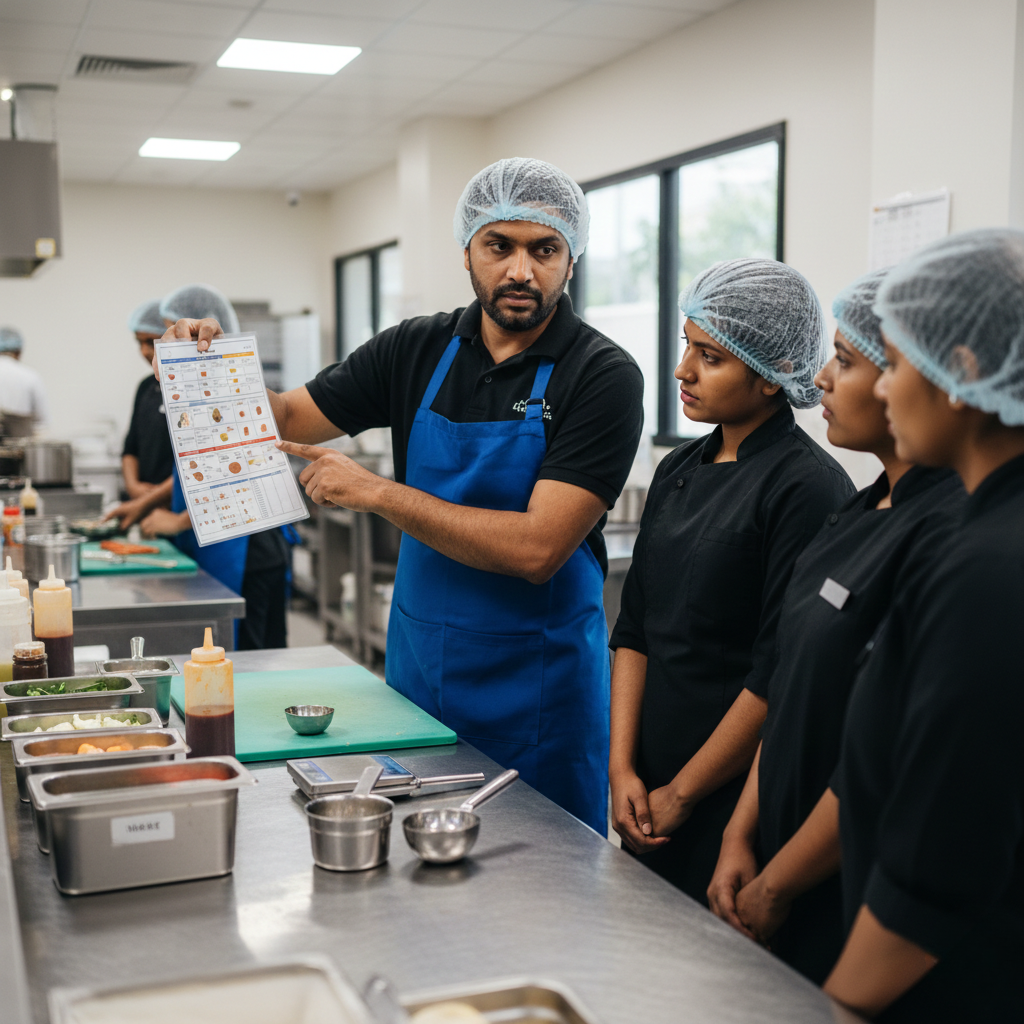

Food Cost Control

Portion tools, yield tracking, and prep discipline.

Menu Engineering

High-margin items, bundles, and add-ons.

Weekly Review Loop

Dashboards that stop drift before losses appear.

Profit Is Protected in Daily Execution

Price changes rarely fix profitability. What actually protects margin is how consistently your kitchen executes every single order-especially during peak.

Portion control prevents silent margin loss

Over-portioning, yield loss, and “just this once” serving habits quietly destroy contribution margin. Fixed tools, prep discipline, and SKU-level SOPs remove guesswork from every plate.

Packing accuracy protects refunds and ratings

Missing items, spills, and wrong variants don’t just cost refunds-they reduce repeat orders and force discounting. Structured packing checklists and label discipline stop errors before they leave the kitchen.

Dispatch speed safeguards repeat demand

Slow handovers and backlog kill ratings. When prep, packing, and dispatch flow are designed as one system, speed improves without adding staff.

Menu & Discount Engineering for Margin

Profitable menus sell margin by default. They don’t rely on founders watching every order.

High-CM Heroes

Items that should dominate your sales mix.

Workhorse Fixes

High-volume items adjusted for margin.

Smart Bundles

Higher AOV without higher food cost.

Discount Guardrails

Never discount below safe contribution margin.

Profitability Runs on Visibility

If profit isn’t reviewed weekly, it will drift monthly.

Daily KPIs

Refunds, prep-to-pack time, order accuracy.

Weekly KPIs

Food cost %, packaging per order, SKU CM.

Monthly KPIs

Contribution margin vs fixed costs.

Review Rhythm

One fix per week. Locked into SOPs.

Want a Profitability System Built for Your Kitchen?

Share your city, monthly sales range, top items, and current food cost. We’ll show you exactly where profit is leaking and how to fix it.

Get a Custom Cloud Kitchen Plan for Your Brand

Not sure how to start or scale your cloud kitchen in India? Share a few details about your brand and we’ll send you a personalised setup and growth roadmap.

- City-wise kitchen and location suggestions

- Approximate investment & profit estimates

- Menu and positioning recommendations

- Whether CKaaS or own kitchen suits you better

Fill the form and our team will get in touch within one working day.

About Us

Ckaas Sloutions

Contact

Follow On

© 2025 Grow Kitchen. All rights reserved.

WhatsApp us