Central kitchens promise scale, cost control, and consistency. Yet in India, many central kitchen models fail silently within 12–24 months. The reason is not food quality, demand, or even capital. Central kitchens fail because processes don’t exist, don’t transfer, or don’t survive scale. This guide explains why central kitchens fail without process consulting, what actually breaks behind the scenes, and how structured process systems determine whether a central kitchen becomes a growth engine or a cash sink.

Why Central Kitchens Fail Without Process Consulting

This article is part of GrowKitchen’s profitability + operations learning series. If you’re new to delivery-first models, start here: Cloud Kitchen Business in India.

Central kitchens amplify both discipline and disorder. Food safety, hygiene, and documentation must align with FSSAI requirements and structured staff training via FoSTaC. Without process control, centralization magnifies risk.

The Central Kitchen Myth

Many founders believe central kitchens automatically reduce cost. The assumption is simple: bulk cooking equals efficiency.

In reality, a central kitchen is not a kitchen upgrade. It is an operational complexity upgrade. Without structured processes, a central kitchen becomes harder to manage than multiple independent kitchens.

The Illusion of Scale Without Process

Central kitchens create the illusion of control. Production looks organized. Bulk buying looks cheaper. Output numbers look impressive.

But beneath the surface, teams struggle with:

- Unclear prep ownership

- Inconsistent batch quality

- No yield accountability

- Dispatch timing mismatches

- High wastage masked by volume

These problems don’t show up on Day 1. They appear when volume increases or outlets multiply.

Why Infrastructure Never Replaces Process

Founders often invest in equipment before investing in process. Bigger kettles, blast freezers, vacuum sealers but no SOPs on how and when to use them.

Equipment without process leads to:

- Overproduction

- Inconsistent holding times

- Unsafe cooling practices

- Untraceable batch failures

Process consulting exists to design systems that infrastructure alone cannot solve.

Where Central Kitchens Actually Break

Central kitchens usually fail at predictable points:

- Batch planning: no demand-linked production planning.

- Yield loss: trimming, cooking loss, spillage not tracked.

- Storage misuse: FIFO violated under pressure.

- Dispatch errors: wrong quantities sent to outlets.

- Accountability gaps: no owner for batch failures.

These issues mirror common failure reasons: Why Cloud Kitchens Fail in India.

What Process Consulting Actually Fixes

Process consulting is not advice. It is system design.

In central kitchens, consulting focuses on:

- End-to-end SOP creation (prep → cook → store → dispatch)

- Batch size logic linked to outlet demand

- Yield and wastage tracking per recipe

- Food safety checkpoints

- Accountability matrices

These systems allow central kitchens to scale without panic.

The People Problem Is a Process Problem

Central kitchen founders often blame staff: “They don’t follow instructions.”

In reality, instructions are rarely documented, visualized, or audited.

Process consulting creates:

- Visual SOP boards

- Role-based task ownership

- Training frameworks

- Audit routines

This reduces dependence on individual skill levels.

Central Kitchens vs Multi-Location Kitchens

Central kitchens are not always superior. They work only when processes are mature.

Many brands scale better first through controlled multi-location kitchens.

Compare models here:

How to Scale Cloud Kitchens

See this – Facebook.

How Central Kitchens Bleed Money Without Process

Central kitchens hide losses through volume.

- Untracked yield loss

- Expired stock

- Re-cooking costs

- Emergency logistics

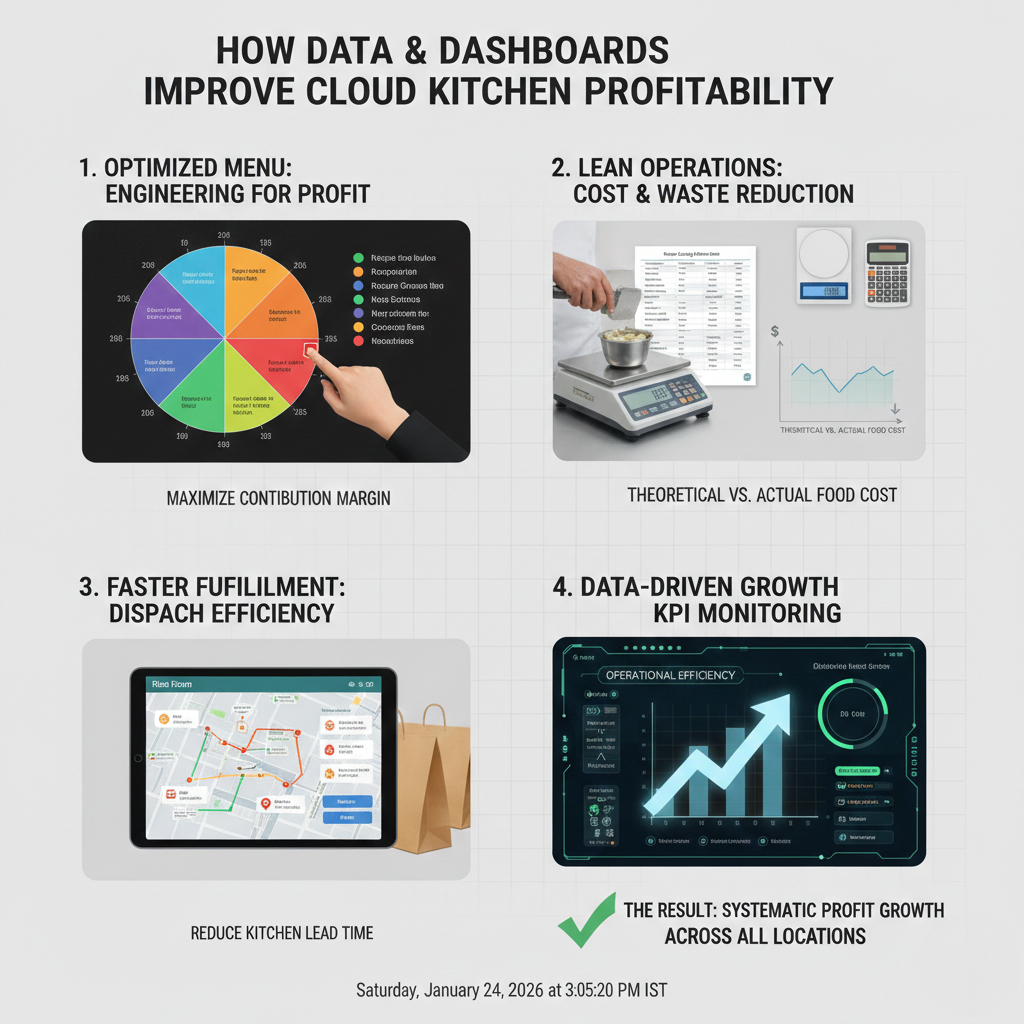

These leaks destroy contribution margin. Understand margin math here: Cloud Kitchen Profit Margin in India.

When Process Consulting Becomes Non-Negotiable

Central kitchens should not operate without consulting when:

- Serving more than 3 outlets

- Producing multiple cuisines

- Handling chilled or frozen inventory

- Running 16+ hour operations

At this stage, founder intuition collapses.

Final Thoughts: Central Kitchens Are Process Businesses

Central kitchens are not food businesses. They are process businesses that happen to produce food.

Without process consulting, scale magnifies chaos. With process consulting, scale becomes predictable.

FAQs: Central Kitchens & Process Consulting

Can a central kitchen run without consultants?

Only at very small scale. As complexity increases, lack of process leads to hidden losses.

Is process consulting expensive?

It costs far less than wastage, recalls, refunds, and failed expansion.

When should consulting start?

Before scale not after failure.