A cloud kitchen SOP checklist is the fastest way to turn “daily chaos” into a repeatable system. It standardizes prep, hygiene, portioning, packing, and dispatch so your kitchen performs the same on Monday lunch rush and Saturday dinner peak. Most cloud kitchen SOP checklist in India don’t fail because food is bad they fail because execution is inconsistent: missing items, cold food, leakage, stockouts, and staff freelancing. This guide gives you a practical 1300-word cloud kitchen SOP checklist you can implement immediately: opening checks, station SOPs, batch prep rules, inventory discipline, packing + dispatch controls, hygiene audits, and the KPIs that warn you before ratings collapse.

Start Here Before Implementing a Cloud Kitchen SOP Checklist

This article is part of GrowKitchen’s operations and scalability series. If you want the delivery-first foundation (how cloud kitchens work, where margins leak), start with: Cloud Kitchen Business in India.

Your SOP checklist must align with food safety and compliance basics such as FSSAI licensing and hygiene requirements, and structured billing + taxation via the GST Network. Weak compliance turns daily operations into a shutdown risk.

Cloud Kitchen SOP Checklist Explained

A cloud kitchen SOP checklist is a documented set of daily and station-wise steps that ensure consistent taste, predictable prep time, safer food handling, and controlled costs. It removes dependence on founder supervision and reduces variability caused by staff changes.

The purpose is simple: stable ratings + stable contribution margin + repeat orders. SOPs achieve that by preventing the most common daily failures: late dispatch, missing items, leakage, portion inconsistency, and stockouts.

The 7 Pillars of a Cloud Kitchen SOP Checklist

A complete SOP checklist isn’t only “cleaning.” It connects daily execution to margin and ratings. Use these seven pillars as your structure if one pillar is missing, the kitchen leaks money quietly.

- Opening Readiness: staff hygiene, station setup, stock quick-scan, equipment checks.

- Food Safety + Hygiene: cleaning schedules, temperature logs, labeling, pest control habits.

- Prep + Batch System: recipes, yields, batch cycles, FIFO storage, hold protocols.

- Portion Control: ladle rules, standard scoops, weigh-points for high-cost items.

- Packing SOP: packaging selection, sealing, labeling, add-on verification.

- Dispatch SOP: ticket aging limits, rider handover rules, peak-hour escalation.

- Daily Reporting: wastage, stock variance, refunds, late dispatch %, top complaints.

If you’re building your overall operations playbook, pair this with: Cloud Kitchen Operation Framework.

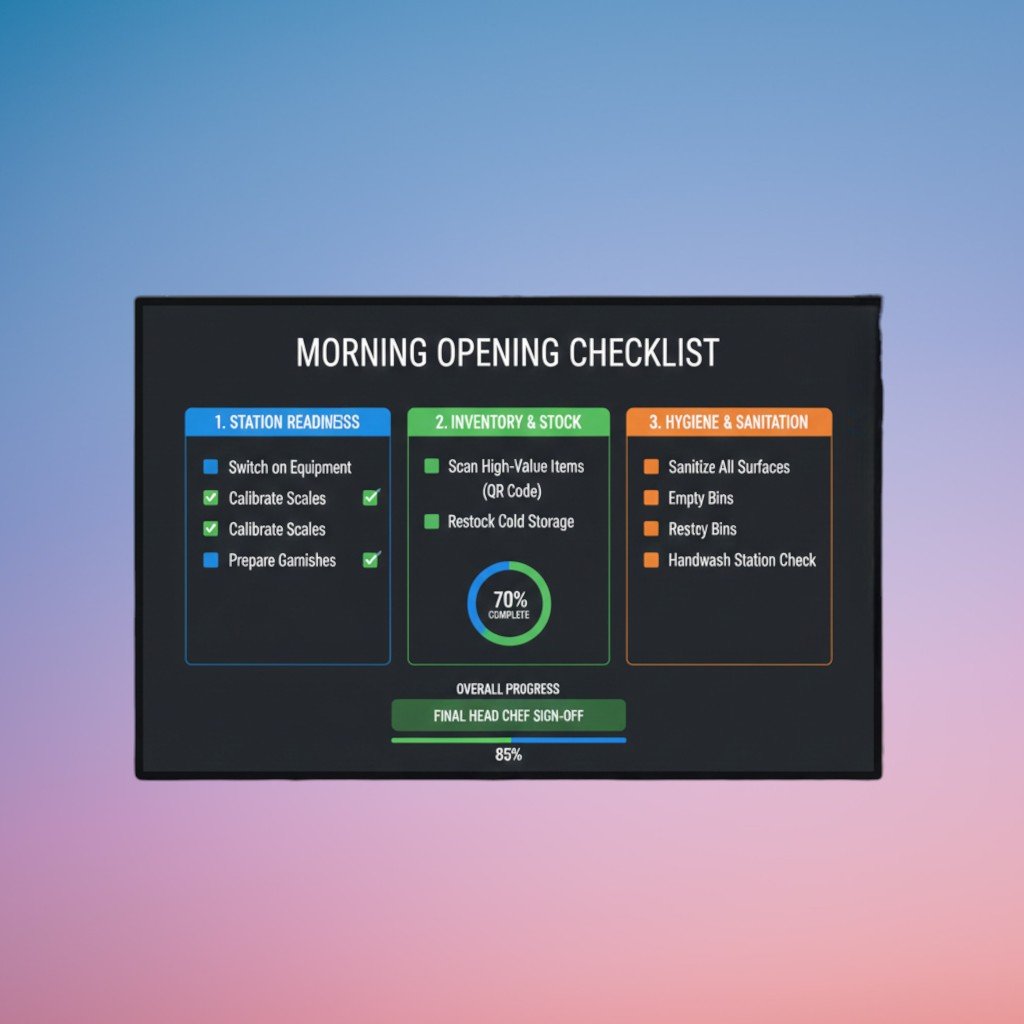

Opening SOP Checklist (First 30-45 Minutes)

The opening checklist decides whether your day runs smoothly or becomes firefighting. A strong opening SOP prevents peak-hour breakdowns by making sure stations are ready and inventory is visible.

- Staff hygiene: clean uniform, hairnet/cap, trimmed nails, handwash protocol followed.

- Kitchen sanitation: surfaces wiped, floors dry, sinks clean, garbage area cleared.

- Equipment checks: gas/induction, fridge temps, freezer temps, weighing scale calibration.

- Water + drainage: running water, drainage flow, no blockages, clean dish area.

- Stock quick-scan: top 20 fast movers available (base gravies, sauces, proteins, packaging).

- Prep plan: batch plan finalized for lunch/dinner peaks (what to prep + quantity).

- Packaging readiness: boxes, bowls, seals, labels, carry bags counted and stocked.

For new kitchens still planning setup and equipment, reference: Cloud Kitchen Setup Cost in India.

Food Safety & Hygiene SOP Checklist (Daily + Weekly)

Hygiene is a daily habit, not an occasional deep clean. Your checklist should be audit-ready: temperature logs, cleaning schedules, and corrective actions documented.

- Temperature logs: cold storage and freezer temperature recorded (opening + mid-shift + closing).

- Raw vs cooked separation: separate containers, separate cutting boards, separate storage shelves.

- Labeling rule: prep date/time, expiry date, batch name, staff initials.

- FIFO rule: older batches used first; expired/unsafe items disposed with wastage entry.

- Handwash SOP: every 30–60 minutes + after handling raw proteins + after cash/phone use.

- Cleaning schedule: hourly wipe-downs for high-contact points; end-shift deep clean for stations.

- Pest control habit: no open food, lids sealed, drains clean, garbage removed on time.

For structured food safety training references, use: FSSAI FoSTaC.

Prep & Batch SOP Checklist (The “Speed + Consistency” Layer)

Batch prep is what makes cloud kitchens scalable. But batch prep without yield tracking and labeling becomes wastage. Your SOP checklist must define what gets batched, how it is stored, and how it is reused safely.

- Batch recipes: documented recipes for bases, gravies, sauces, marinations, spice mixes.

- Yield tracking: expected yield per batch (example: 5 kg gravy yields 40 portions).

- Batch timing: prep cycles aligned to peaks (morning prep for lunch; afternoon top-up for dinner).

- Cooling SOP: hot-to-cold transfer done safely (avoid unsafe temperature zones for long periods).

- Hold protocol: hot holding rules + cold storage rules + reheat SOP for components.

- Labeling: batch name + timestamp + expiry + staff initials mandatory.

- Discard rule: clear expiry cutoff for each batch item (no “smell test” decisions).

If you’re running multiple brands from one kitchen, prep discipline becomes even more important: Scalable Cloud Kitchen Business Model in India.

Portion Control SOP Checklist (Margin Protection)

Portion inconsistency is the #1 silent profit killer. Your checklist must enforce standardized scoops, ladles, and weigh-points for high-cost ingredients. Without portion control, food cost % drifts slowly and ROI collapses.

- Standard scoops/ladles: assigned per item (sauce, gravy, rice, toppings).

- Weigh-points: proteins, paneer, cheese, premium toppings weighed every time.

- Recipe card at station: SKU photo + portion quantities visible at the assembly line.

- Daily random checks: manager checks 5–10 random orders for portion compliance.

- Weekly food cost by SKU: track per item, not just overall kitchen average.

For margin math and contribution control, pair this with: Cloud Kitchen Profit Margin in India and Cloud Kitchen ROI in India.

Packing SOP Checklist (The “Ratings Protection” Layer)

Packing is where good food becomes a great delivery experience or a refund. Your packing SOP checklist must standardize packaging types, sealing rules, and verification steps.

- Packaging selection: vented boxes for fried items, leak-proof bowls for gravies, separation for crunchy sides.

- Sealing rule: tamper seal on every order; leakage test for gravy-heavy items.

- Labeling: order ID, brand name, item count, allergen note (if applicable).

- Add-on verification: extra dip, beverage, dessert, cutlery (if offered) checked before sealing.

- Photo standard: ensure product presentation matches listing photos (avoid “customer shock”).

- Pack QC sign-off: packer initials (creates accountability).

If your kitchen struggles with aggregator pressure and pricing, keep your strategy clear: How to Reduce Swiggy Commission.

Dispatch SOP Checklist (Speed + Control)

Dispatch is not “handover to rider.” Dispatch is a timing system. The SOP should define ticket aging limits, rider staging, and escalation steps during peak congestion.

- Ticket aging limit: maximum time from “ready” to “handover” (set a strict target internally).

- Rider staging: dedicated pickup area; no rider crowding inside production line.

- Peak escalation: when orders spike, assign one person only for dispatch + rider coordination.

- Missing-item prevention: sealed packs only handed over after checklist verification.

- Delay reason log: if dispatch delays happen, reason must be recorded (prep, packaging, rider wait).

If dispatch delays and low ratings are frequent, this failure breakdown helps: Why Cloud Kitchens Fail in India.

Inventory + Daily Reporting SOP Checklist (Stop Silent Leakage)

Your checklist should end with reporting because what gets measured gets controlled. Inventory and reporting SOPs prevent stockouts, reduce wastage, and reveal theft/leakage early.

- Daily wastage log: expiry, spillage, returns, overproduction categorized, not vague.

- Stock movement update: top items updated daily (or after each peak).

- Reorder triggers: par levels checked for key items and packaging.

- Refund & complaint log: reason codes (cold, late, missing, spillage) + corrective action note.

- Weekly stock variance: purchased vs expected vs actual (catch drift early).

For billing/tax structure references for food businesses, use: GST Network.

Weekly KPI Checklist (Early Warning System)

SOPs run the kitchen daily. KPIs tell you whether SOPs are working. These are the weekly checks that predict failure early before ratings collapse.

- Contribution margin per order (by SKU + channel)

- Food cost % (overall + top SKUs)

- Dispatch delay % during peaks

- Refund rate and top complaint reasons

- Rating variance (stability matters more than one good week)

- Repeat rate (week 1 → week 4 retention)

If you’re preparing to scale to new locations, align SOP checks with: Cloud Kitchen Expansion Strategy in India.

Final Thoughts: Cloud Kitchen SOP Checklist

A cloud kitchen SOP checklist is the simplest tool that creates the biggest operational shift: it replaces memory with repeatability. When your opening checks are consistent, prep is batch-driven, portioning is controlled, packing is verified, and dispatch follows timing rules your kitchen becomes predictable.

Predictability is what builds profitability and scale. Not more discounts. Not more ads. Systems. Implement the checklist, audit it weekly, and improve it monthly.

FAQs: Cloud Kitchen SOP Checklist

What is a cloud kitchen SOP checklist?

It’s a documented list of daily and station-wise operating steps that standardizes hygiene, prep, portioning, packing, dispatch, and reporting so the kitchen performs consistently without founder dependence.

Which SOP impacts ratings the most?

Packing and dispatch SOPs. Leakage, cold food, missing items, and late handovers reduce ratings even when taste is strong.

How often should I audit SOP compliance?

Do quick daily checks (opening + closing) and a structured internal audit weekly. Review KPI trends weekly to catch drift early.

What should I create first: SOPs or dashboards?

SOPs first. Dashboards work only when execution is standardized enough to generate reliable data.