A centralized cloud kitchen model in India is the “hub” approach to scaling food delivery: one large production kitchen serving a wider catchment area-sometimes supported by smaller dispatch points. It can unlock powerful unit economics through batch prep, procurement control, and SOP discipline. But if you ignore delivery radius, food quality decay, and dispatch timing, the same model can silently destroy ratings. This guide explains how the centralized cloud kitchen model works in India, when it wins, when it fails, and how to design it for predictable scalability.

Start Here Before Building a Centralized Cloud Kitchen

This article is part of GrowKitchen’s scaling models and operations series. If you’re new to delivery-first kitchens, start with: Cloud Kitchen Business in India.

Any centralized kitchen handling high volumes must stay compliant with FSSAI, maintain proper invoicing and taxation via GST Network, and follow local municipal norms for waste, water, fire safety, and labor.

What Is a Centralized Cloud Kitchen Model in India?

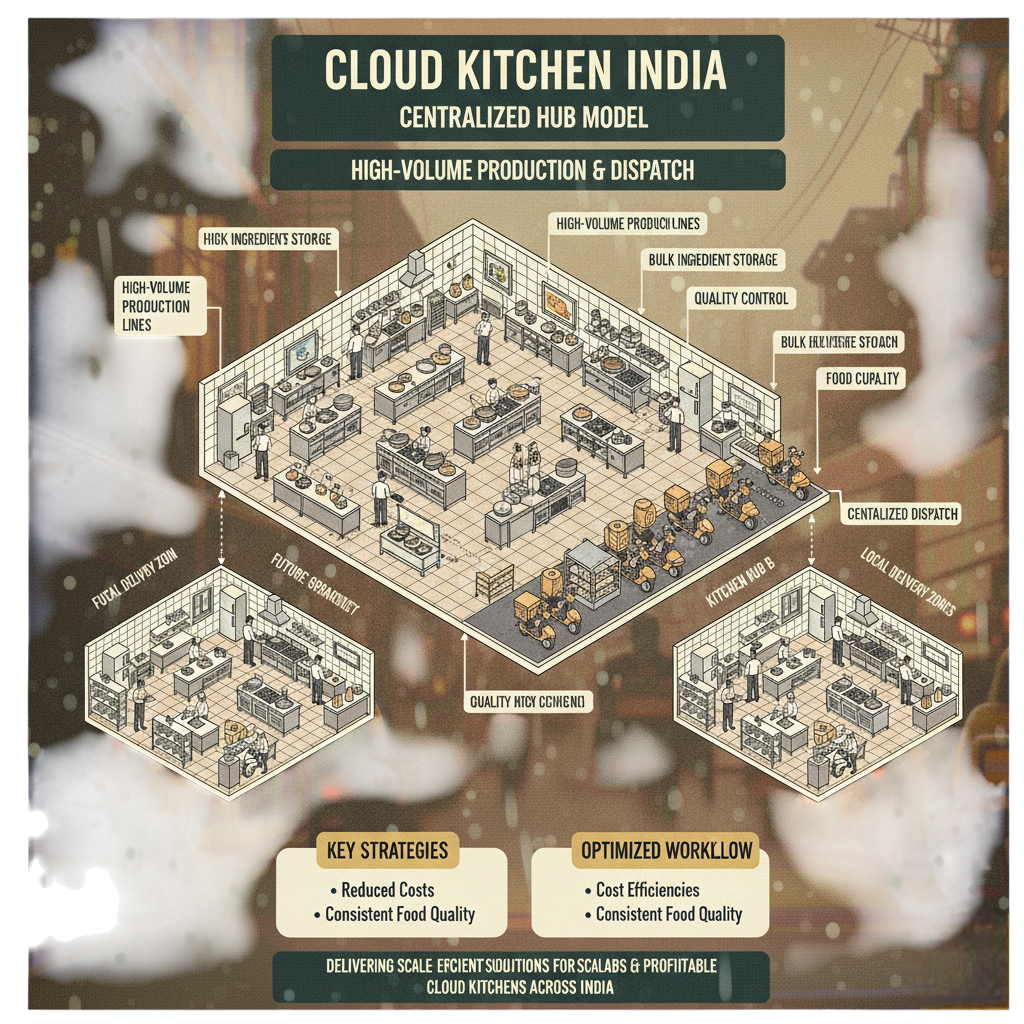

A centralized cloud kitchen model is a production-heavy setup where one primary “hub kitchen” prepares food for delivery across multiple neighborhoods. Instead of running many small kitchens close to customers, the centralized model concentrates infrastructure, staff, procurement, and SOP control into one location.

In India, this model is commonly used by brands that want stronger quality control, lower per-unit raw material costs, and standardized taste across a city-especially when the menu is designed for batch production.

How the Centralized Cloud Kitchen Model Works

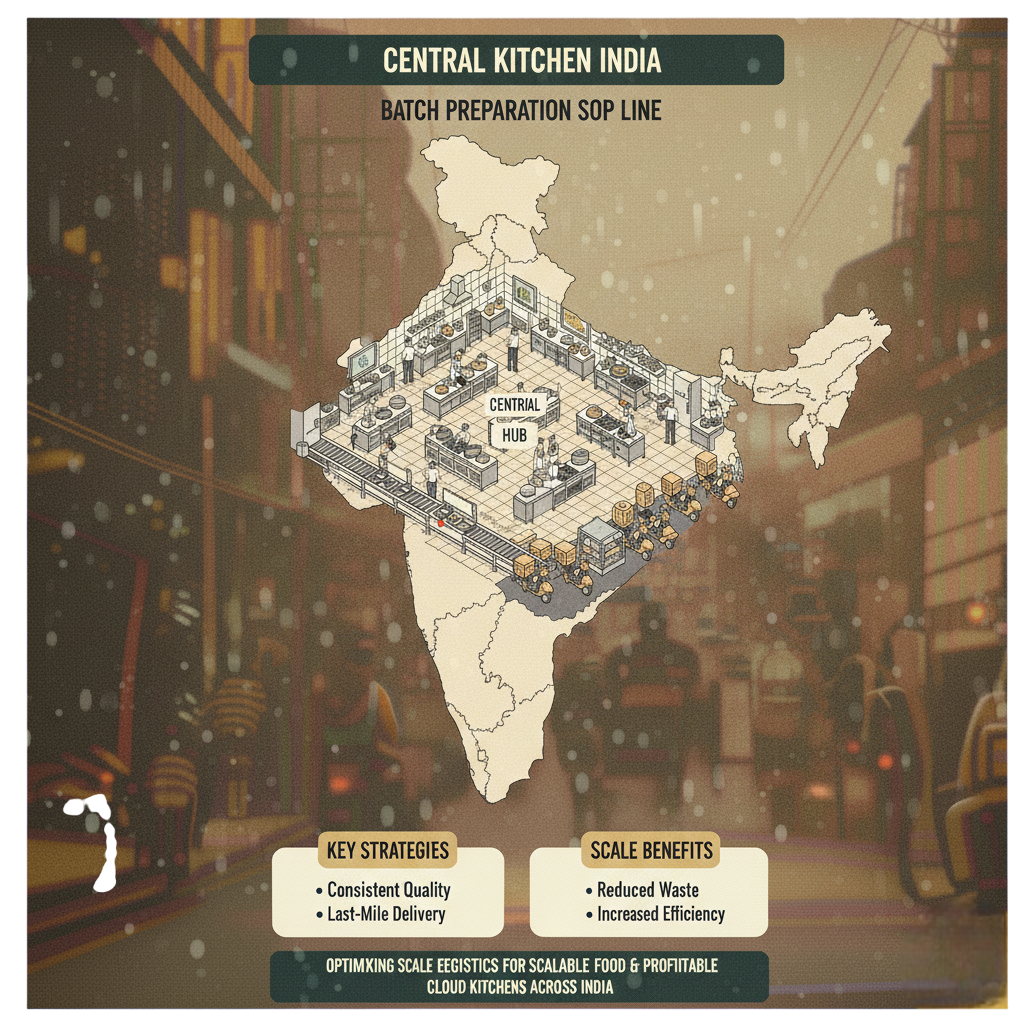

The centralized model usually runs in three layers: production (batch prep), assembly (order line), and dispatch (handover to delivery). The operational advantage is simple: fewer kitchens means fewer variations, fewer vendor issues, and tighter cost control-if your SOP execution is strong.

A mature centralized setup typically includes:

- Central procurement and quality checks (single vendor master, negotiated pricing)

- Batch prep stations (mother gravies, sauces, marinations, par-cooked components)

- Assembly line with portion control (ladle rules, weighing points, standardized packaging)

- Dispatch discipline (KDS timings, rider handover, heat retention packaging)

- Real-time inventory tracking and wastage reporting

If you don’t already operate with SOP discipline, fix that first: Cloud Kitchen SOP Checklist.

Centralized vs Distributed Cloud Kitchens: What’s the Real Difference?

Centralized cloud kitchens (multiple small kitchens) win on delivery speed and freshness because they sit closer to customers. Centralized kitchens win on cost control and consistency because they reduce operational duplication.

Here’s the simplest decision rule:

- Choose centralized if your menu holds well, batch prep is possible, and you want lower cost-per-order.

- Choose distributed if your menu quality drops with time, or if 25–35 minute deliveries kill ratings.

If your goal is to scale to multiple locations later, study the replication playbook: How to Scale Cloud Kitchens.

When a Centralized Cloud Kitchen Wins in India

Centralization works best when your food quality remains stable during delivery and your operations benefit from batch production. In Indian cities, centralized kitchens often win for:

- High-volume staples with predictable demand (rice bowls, curries, gravies, biryani components)

- Standardized menus where taste consistency matters more than “fresh off the pan” theatrics

- Corporate meals and bulk ordering (planned dispatch windows, controlled batching)

- Multi-brand operations that share raw materials (shared bases + differentiated toppings)

- Founder-led quality control where one hub is easier to monitor than 6 scattered kitchens

If you’re designing your economics, pair this with margin fundamentals: Cloud Kitchen Profit Margin in India.

The Hidden Risks That Break Centralized Models

The centralized model fails when it tries to behave like a distributed model. Founders often promise “fast delivery” while operating from a hub far from customers. The outcome is predictable: delayed deliveries, soggy food, low ratings, higher refunds, and higher ad spend to compensate for poor repeat rates.

The biggest risk zones:

- Delivery radius mismatch: the hub is too far from dense demand clusters

- Food quality decay: fried/crispy items, delicate textures, and temperature-sensitive products suffer

- Dispatch bottlenecks: peak-hour order spikes overwhelm a single kitchen if the line isn’t designed

- Aggregator dependency: heavy Swiggy/Zomato reliance compresses margins if you don’t price correctly

- Weak packaging engineering: steam traps, leakage, and heat loss destroy repeat orders

A deeper breakdown of what kills kitchen performance: Why Cloud Kitchens Fail in India.

Unit Economics in a Centralized Kitchen: What Improves, What Gets Harder?

A centralized model improves procurement power, reduces per-unit prep effort through batching, and cuts duplicated fixed costs. But it also introduces new cost lines that founders underestimate: more robust packaging, higher dispatch management, and potentially higher delivery time penalties.

In practical terms, centralized kitchens usually gain ROI through:

- Bulk buying and vendor consolidation (lower raw material rate)

- Batch prep productivity (less labor per order)

- Standardized wastage control (better forecasting + tighter FIFO)

- Consistent taste (higher repeat rate if delivery radius is managed)

But ROI becomes fragile if you chase vanity revenue without contribution margin control: Cloud Kitchen ROI in India.

Design Playbook: Building a Centralized Cloud Kitchen That Scales

If you want centralization to work in India, design the kitchen like a production system-not a restaurant. Your goal is repeatable output, predictable quality, and controlled timings. Here’s a field-tested design playbook:

- Menu engineering first: build around batch-friendly bases + fast assembly (avoid 40-item chaos menus)

- Station layout: receiving → storage → prep → cook → hold → assembly → QC → dispatch

- Portion control: ladle rules, standard scoops, weighing checkpoints on high-cost ingredients

- Batch rhythm: prep cycles that match demand peaks (lunch + dinner) without overproducing

- Packaging engineering: vented boxes, moisture control, separation for crunchy components

- Dispatch rules: ticket aging limits, rider staging, handover SOP, escalation during spikes

If you’re still working out setup budgets and equipment decisions, use: Cloud Kitchen Setup Cost in India.

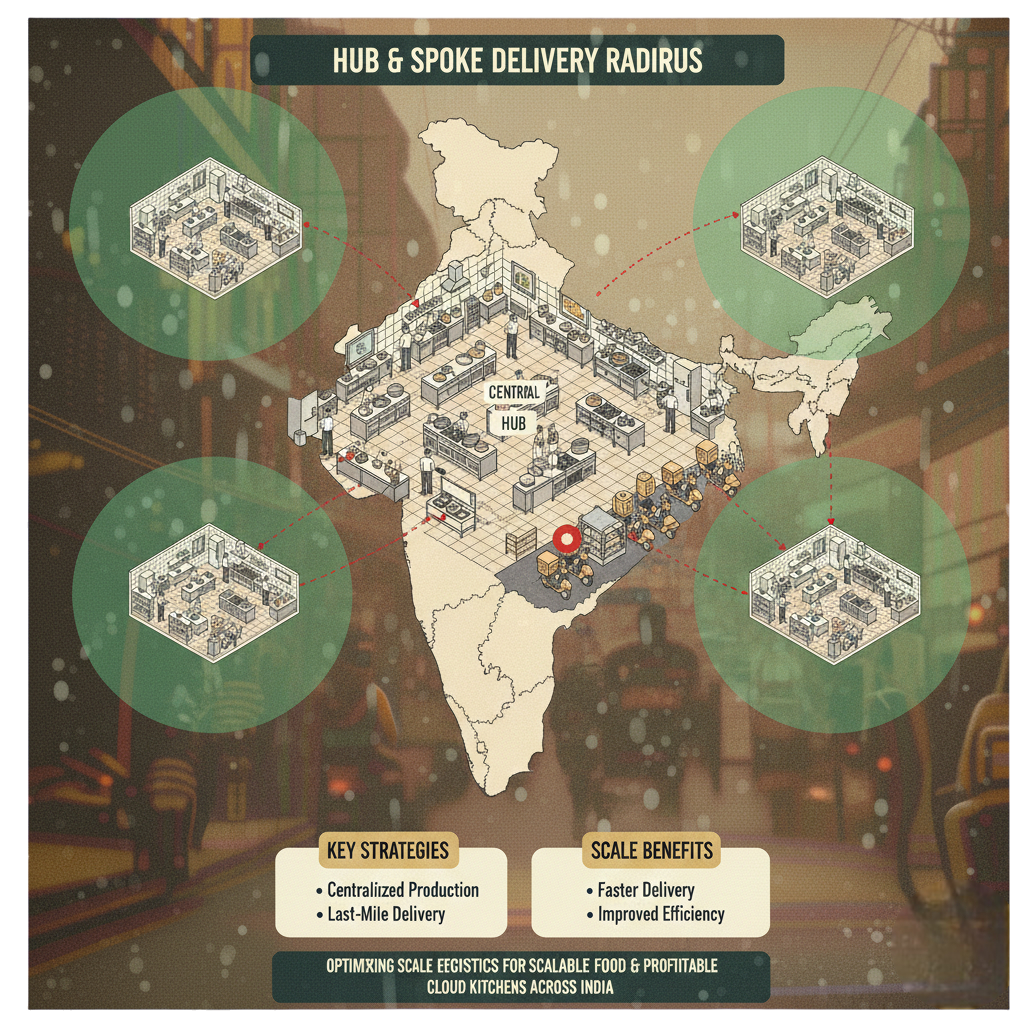

Hub-and-Spoke: The Hybrid Model Most Indian Cities Need

Pure centralization can struggle in large, traffic-heavy cities. That’s why many brands evolve into a hybrid: one central production hub plus small “spokes” for final assembly/dispatch (or ingredient holding). This keeps quality high while still enjoying centralized procurement and batch prep advantages.

Typical “spoke” roles include:

- Final assembly and packing close to dense demand clusters

- Holding of prepped components (cold storage + retherm protocols)

- Faster dispatch windows (especially dinner peak)

If your growth depends heavily on aggregators, keep your commission strategy tight: How to Reduce Swiggy Commission.

Operational Checklist for Centralized Kitchens

Centralization magnifies both strengths and mistakes. A small SOP gap becomes a daily leak at scale. Your kitchen should be able to answer “yes” to these operational questions:

- Do we track food cost % by SKU weekly (not monthly)?

- Do we have standard prep yields and batch recipes documented?

- Do we have a hard rule for maximum ticket aging before dispatch?

- Do we audit packaging performance with real delivery feedback?

- Do we run a daily wastage and stock variance review?

- Do we have peak-hour staffing and fallback plans?

If the answer is “no” to more than two, fix systems before you scale.

Final Thoughts: Centralized Cloud Kitchen Model in India

A centralized cloud kitchen model in India can be a serious profit engine-when it’s built like a production system, not a restaurant. It wins on procurement, SOP control, and consistent taste. But it loses quickly when delivery radius is unrealistic or when menus are not engineered for holding and transport.

The best operators use centralization for what it’s meant for: predictable output, stable margins, and scalable replication-and then add spokes only where delivery speed and freshness demand it.

FAQs: Centralized Cloud Kitchen Model in India

What is a centralized cloud kitchen model?

A single hub kitchen handles production and dispatch for a wider area, instead of multiple small kitchens across the city.

Is centralized cloud kitchen better than multiple locations?

It’s better for cost control and consistency. Multiple locations are better for delivery speed and freshness.

What is the biggest risk in a centralized kitchen?

Delivery radius mismatch-long delivery times reduce ratings and repeat orders, even if food is good.

How do brands fix centralized delivery speed issues?

By using a hub-and-spoke setup: centralized production with smaller dispatch points closer to demand clusters.